From classic black and primary colors, to more custom shades of blue and gray, click on each color to view our product specs and request a complimentary vinyl leather or laminate vinyl sample.

Vinyl Samples & Colors

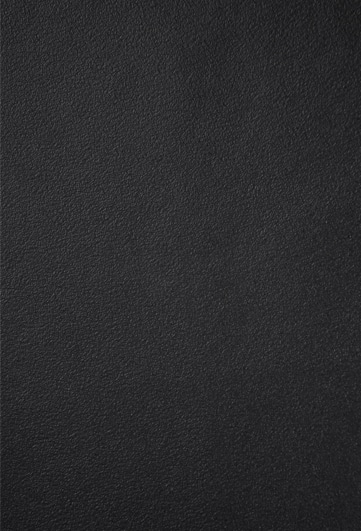

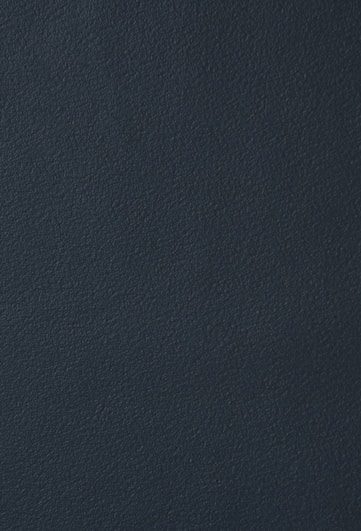

Cayman Expanded Vinyl

Cayman Charcoal

Cayman Charcoal

Material: Marine Supported Vinyl

Dimensions: 54″

Yards per roll : 50

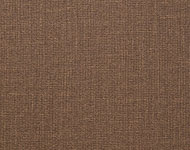

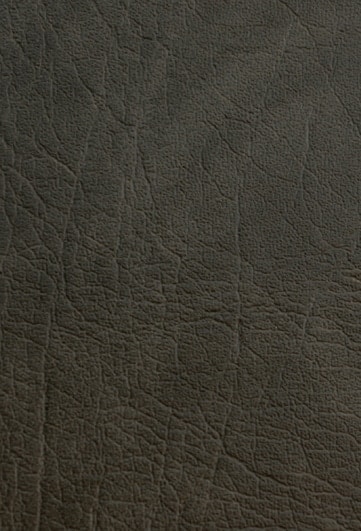

Cayman Coffee Bean

Cayman Coffee Bean

Material: Marine Supported Vinyl

Dimensions: 54″

Yards per roll : 50

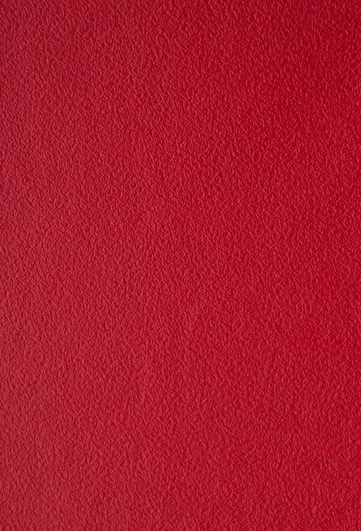

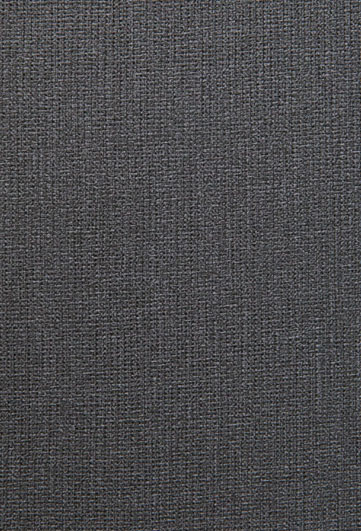

Bermuda Expanded Vinyl

Bermuda Bright Yellow

Bermuda Bright Yellow

Material: Supported Vinyl

Dimensions: 54″

Yards per roll : 40

Pelican Expanded Vinyl

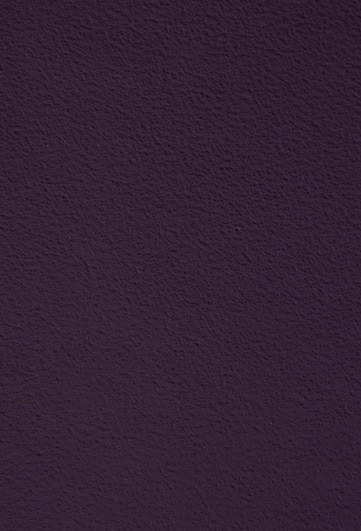

Pelican Burgundy

Pelican Burgundy

Material: Marine Supported Vinyl

Dimensions: 54″

Yards per roll : 50

Pelican Butterscotch*Special Order Only

Pelican Butterscotch*Special Order Only

Material: Marine Supported Vinyl

Dimensions: 54″

Yards per roll : 50

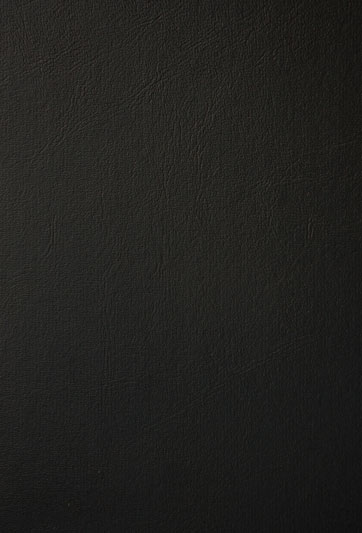

Pelican Charcoal

Pelican Charcoal

Material: Marine Supported Vinyl

Dimensions: 54″

Yards per roll : 50

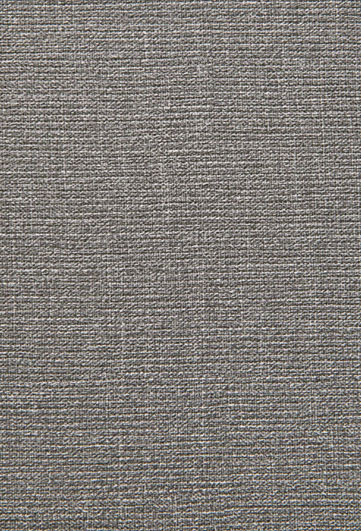

Pelican Granite

Pelican Granite

Material: Marine Supported Vinyl

Dimensions: 54″

Yards per roll : 50

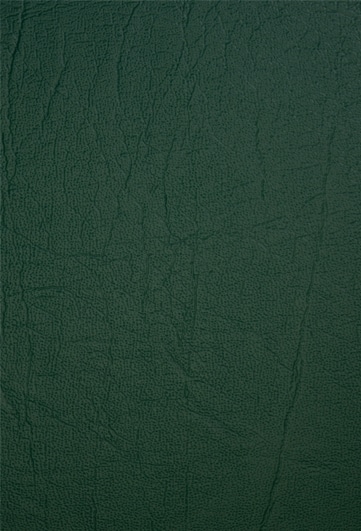

Pelican Hunter Green

Pelican Hunter Green

Material: Marine Supported Vinyl

Dimensions: 54″

Yards per roll : 50

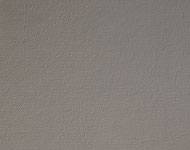

Pelican Light Gray

Pelican Light Gray

Material: Marine Supported Vinyl

Dimensions: 54″

Yards per roll : 50

Pelican Redwood* Special Order Only

Pelican Redwood* Special Order Only

Material: Marine Supported Vinyl

Dimensions: 54″

Yards per roll : 50

Pelican Tropical Blue* Special Order Only

Pelican Tropical Blue* Special Order Only

Material: Marine Supported Vinyl

Dimensions: 54″

Yards per roll : 50

Fuzzyback, Bonneville, Formulation B & Wallaby

Formulation B Black* Special Order Only

Formulation B Black* Special Order Only

Material: Fuzzyback Film

Yards per roll: 75

Formulation B White* Special Order Only

Formulation B White* Special Order Only

Material: Fuzzyback Film

Yards per roll: 75

View the Full Product ListRequest a Sample

Due to monitor settings, monitor pixel definitions, limitations of desktop scanners, digital photography, and dye lot variations, we cannot guarantee that the colors displayed exactly represent our products. We strive to present colors as accurately as possible. Product images are intended as a guide only. All colors are approximations of actual colors.