Extrusion is a versatile process used to create a variety of plastic products such as films and sheeting. Although this process is compatible with various materials, PVC is especially popular due to its many desirable characteristics. When manufacturing extruded PVC sheets, the raw material is heated to a melted state before being forced through a die from which it exits at the desired width and thickness. Once the sheet has cooled, it can be cut into strips or rolled for later use. At Adam Plastics, we offer a variety of extruded PVC products, including extruded PVC strips and sheets.

Extruded PVC Strip

PVC strip is a versatile product that is available in many widths, thicknesses, and formulations to best meet the requirements of a variety of applications.  While the most common PVC strip is clear, we at Adams Plastics, offer a few options – such as clear, tinted, and opaque colors. Standard clear PVC is a popular choice for strip doors, curtains, and partitions in industrial and commercial facilities that need barriers that don’t obstruct visibility. Cleanrooms and manufacturing facilities use these curtains to minimize or eliminate the risk of contamination across different zones in the facilities. Cold storage facilities and warehouses can use them for temperature control to prevent chilled air from dissipating throughout the building. Welders also commonly use extruded PVC curtains to contain welding areas for safety compliance.

While the most common PVC strip is clear, we at Adams Plastics, offer a few options – such as clear, tinted, and opaque colors. Standard clear PVC is a popular choice for strip doors, curtains, and partitions in industrial and commercial facilities that need barriers that don’t obstruct visibility. Cleanrooms and manufacturing facilities use these curtains to minimize or eliminate the risk of contamination across different zones in the facilities. Cold storage facilities and warehouses can use them for temperature control to prevent chilled air from dissipating throughout the building. Welders also commonly use extruded PVC curtains to contain welding areas for safety compliance.

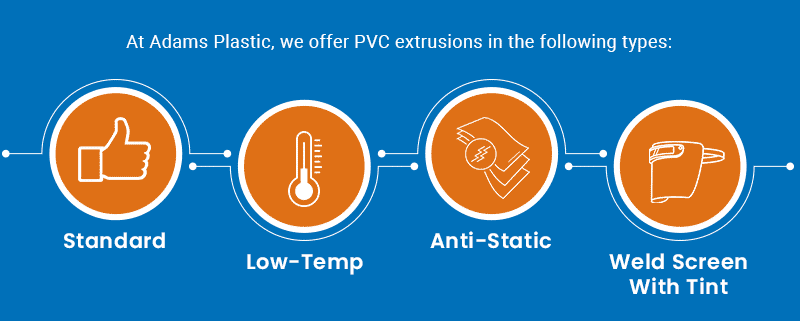

At Adams Plastic, we offer PVC extrusions in the following types:

- Standard. Standard PVC materials offer heat and noise insulation, flexibility, and clarity so doorways and factory floor areas aren’t obstructed. The material is also resistant to impact, scratches, and chemical damage.

- Low-Temp. This PVC is formulated to offer softer formulation for use in cold storage or other low-temperature conditions. Low Temp is recommended for freezer and extreme cold applications to remain more flexible and resist cracking under those conditions. It can contain cooled air while still allowing for easy passage between areas. This material can perform in areas with temperatures as low as -20°F.

- Anti-Static. Its anti-static properties dissipate energy to minimize the risks of sparks and static electricity. Anti-static is commonly used in clean room applications to help control dust. This material can be used in areas with static electric sensitivity, such as areas with electronics, such as mines and some laboratories.

- Weld Screen With Tint. This material is tinted to help reduce the risk of eye damage that welding tools may cause. While direct welders and technicians are wearing eye protection, employees passing by the area may not be. Tinted weld screens keep the area safe for passersby. Weld Screen is not suitable for direct viewing and proper eye protection should still be maintained in those instances.

We also offer both smooth strips and ribbed strips to best meet our clients’ needs for durability. The extruded strips can range from 6″ to 16″ wide.

Extruded PVC Sheet

At Adams Plastic, we also distribute wider extruded sheets of PVC material for use in a variety of industrial applications. We can supply high-quality PVC sheets that range from 24″ to 48″ inches wide and between 0.04″ to .375” thick. Our sheets are also available in standard, low temp, anti-static, and weld screen varieties to best meet your facility’s safety or production needs.

Extruded Plastics From Adams Plastics

At Adams Plastics, we’re an industry leader in providing PVC strips, sheets, films, and more. We’ve been supplying plastics since 1967, and our team has decades of experience bringing customized PVC solutions to our customers. To learn more about our PVC products, contact us today or request a quote to start your order. Our team is here to help you get the plastic materials you need on schedule and without errors.