Category Archive: PVC

When it comes to various outdoor needs like tents, tent windows, enclosures and more, there are few products superior to vinyl. From its flexibility and versatility to resistance to various threats or risks, vinyl is a high-quality product that’s perfect for your outdoor uses.

At Adams Plastics, we’re proud to offer a wide range of tent and awning window film products for our clients, with products perfect for a variety of needs. Our Prime Crystal Clear, for instance, is a premium flexible PVC roll stock that comes with several major benefits, including flame retardation and cold crack properties that make it ideal for outdoor needs. Let’s go over some of the top applications of vinyl for tents and other outdoor enclosures, plus why clear plastic vinyl is so beneficial in many such settings.

Application of Vinyl for Tents

When it comes to tents and tent windows, vinyl is a superior product in many ways. Our double-polished tent vinyl, for instance, contains several important properties:

- Flexibility: The flexibility of our vinyl tent products means that they can conform to various shapes and sizes, making them perfect for tents of all types.

- Flame retardation: If you need tent fabric that is flame resistant, we have that too. One of our vinyl tenting products is certified to meet the CPAI-84 (Flame Certification for Tent Fabrics) standard, meaning that it won’t catch fire easily and will help keep your tent safe.

- Cold crack properties: Our vinyl can withstand cold temperatures without cracking or breaking, making it ideal for use in tents in colder climates.

Our stock is rated for 1,000 hours, plus is totally transparent and resistant to UV rays. Sewing and welding processes are both acceptable, as well.

For these reasons, common uses of vinyl in this setting are wide-ranging. They’re used in tent windows, boat window covers, vehicle window and seat covers, and even for many outdoor event types like weddings or parties.

Application of Vinyl for Restaurant Patio Enclosures

Another fantastic application for our clear vinyl products is in restaurant patio enclosures. For many restaurants, having an outdoor seating area is essential, but the elements can often make it difficult to keep such areas open year-round. That’s where our clear plastic vinyl comes in, as it can be used to create beautiful and functional patio enclosures that will protect your patron.

With the ability to custom cut our vinyl products to fit your needs, you can create an enclosure that’s perfect for your patio space.

Benefits of Clear Plastic Vinyl

Zooming out just a bit, why is clear plastic vinyl so ideal for many of the uses we’ve gone over here? For several reasons:

- Flexibility: As we mentioned, the flexibility of our vinyl products makes them perfect for a variety of settings and needs.

- Moisture resistance: All of our vinyl products are waterproof and resistant to moisture, making them ideal for outdoor use.

- UV resistance: Our products are also resistant to UV rays, meaning that they won’t fade or degrade over time.

- Durability: You don’t have to worry about our products tearing or breaking easily – they’re built to last.

- Optical clarity: Thick vinyl gauges provide excellent optical clarity, making them ideal for tent windows and other applications where you need to see clearly.

- Ease of maintenance: Our products are also easy to clean and maintain, so you can keep them looking like new for years to come.

For tents and other outdoor enclosures, these properties make vinyl an ideal material. It’s strong and durable yet still flexible, plus it resists moisture and UV rays while providing excellent optical clarity.

For more on this, or to request a quote for any of our high-quality vinyl and plastic needs, speak to our professional team at Adams Plastics today.

PVC is a vinyl material built for durable products that fit the needs and requirements of a range of industries, including:

- Automotive

- Coated fabrics production

- Construction

- Electronics

- Healthcare and medical

- Sport

In the medical and healthcare industries, drainage bags are commonly made from PVC due to its biocompatibility and durability.

Adams Plastics delivers clear PVC vinyl for medical applications to meet the growing demands of the industry. Keep reading to learn more about the types of drainage bags used in the medical industry and the benefits of choosing clear PVC vinyl from our company.

What Are Vinyl Drainage Bags?

Vinyl drainage bags are used throughout the medical field to hold urine and other fluids. Having versatile options and access to different types of vinyl drainage bags allows patients, caretakers, and medical staff to choose the best fit for different circumstances.

While larger bags are designed to last overnight or during daily shifts in a hospital, smaller mobile bags should generally be emptied two or three times a day. The bags themselves are built to last for a month with proper cleaning and care. They’re constructed from durable vinyl that’s easy to clean and inspect for problems.

What Are the Types of Drainage Bags?

Multiple different styles and sizes of drainage bags exist to give users as much flexibility and comfort as possible. A few of the most popular types of bags are vinyl urinary leg, bed drainage bags, and hospital/surgical drainage bags.

- Leg Drainage Bag: These are built for daytime use and people who lead an active lifestyle. They can be comfortably concealed under skirts or pants while securely holding urine. Each bag pairs with elastic straps that hold the bag in place against a wearer’s low inner thigh. These bags are durable, but small for easier wear and concealment. They will need to be monitored and emptied more frequently.

- Bedside Drainage Bag: These larger drainage bags are built to hang on a hook at the user’s bedside. They hold a greater volume of urine throughout the night.

- Healthcare/Surgical Drainage Bag: These PVC bags are often used in surgical applications to hold fluids in a sterile environment and provide easy fluid level monitoring abilities to the surgical staff.

Why Use Vinyl for Drainage Bags?

Just like it’s important to choose the right design and style, it’s important to choose the best-fit material. Vinyl is tough, durable, and resistant to physical and chemical damage. Users can easily clean it without causing damage. The vinyl is also transparent, which allows users and caretakers to determine when it needs to be emptied, if urine is indicating signs of a greater health problem, or if the bag is developing mold. Vinyl is an excellent choice for mobile users, patients receiving at-home care, and patients who are restricted to hospital beds during surgeries and other treatments.

How Does a Drainage Bag Help a Patient?

Fluids accumulating at the wound site can negatively interfere with the wound’s ability to heal. Drainage bags are designed to help prevent this outcome. They may function by using the force of gravity, known as passive or gravity drains, or they could be connected to a larger system that creates suction to move the fluid into the bag or bottle, known as vacuum drains.

Aerosol drainage bags are a type of drainage bag that is specifically designed to prevent accumulated liquid and condensation from reaching patients’ airways during nebulizer treatment.

Additionally, patients who have a catheter installed in their bladder need a portable option for hygienically containing and disposing of urine throughout the day and night. Such drainage bags are a convenient option that users can discreetly wear on their person or hang nearby while still having little to no interruption to their day.

Lastly, surgical bags allow medical professionals to easily dispense vital medications and keep patients hydrated during procedures. These bags are intended to assist users with:

- Urinary incontinence

- Urinary retention

- Fluid Buildup Prevention

- Gentle Wound Drainage In Sensitive Tissue

- Comfort during surgical procedures and other healthcare applications

Why Choose Adams Plastics for Your Vinyl Films and Clear PVC Vinyl

Clear PVC vinyl from Adams Plastics is a strong, flexible material that can be used to create discrete, conveniently shaped, and sized bags. The material is also cost-effective, mitigates the risk of infection, and can be used for single-use applications. Since sterilization is so important for medical devices, PVC is particularly useful because it can be cleaned and sterilized through radiation, the application of ethylene oxide, and steam cleaning.

Place Your Clear PVC Vinyl Order Today

Clear PVC vinyl is an easy choice for hygienic drainage bags for daytime, nighttime, and surgical use. Contact us at Adams Plastics today to request a quote and start your order.

At Adams Plastics Inc, a PVC film supplier for numerous industries, we focus on providing our clients with numerous vinyl options and colors suitable for use in many end-use applications, including industrial curtains. Vinyl curtains are very popular with industrial and commercial businesses as they offer an easy and inexpensive option to improve the work environment.

At Adams Plastics Inc, a PVC film supplier for numerous industries, we focus on providing our clients with numerous vinyl options and colors suitable for use in many end-use applications, including industrial curtains. Vinyl curtains are very popular with industrial and commercial businesses as they offer an easy and inexpensive option to improve the work environment.

Applications of Industrial Curtains

Industrial curtains can divide warehouses, manufacturing facilities, or any workspace to environmentally separate one area from another. They help to create a more comfortable, safe and organized working condition. Industrial curtains provide users with a high-quality, durable, custom-made wall or divider that has specific advantages, such as increased visibility with clear vision panels, noise reduction, and environmental control of dust and temperature, creating a cleaner, safer, and more comfortable work area. Industrial curtains can also lead to significant savings on energy costs.

Properties and Compositions of Industrial Curtains

Industrial curtains are often fabricated using clear vinyl and weld screen tints as stocked by Adams Plastics. Fabricators add grommets, snaps, weighted hems, and other custom options to best meet the needs of the applications. Curtains can be wall-mounted or ceiling suspended as a sliding curtain with a roller track, a roll-up/drop-down configuration, or even a free-standing screen or fixed wall. Our team at Adams Plastics, Inc, provides the materials to create these industrial curtains and partitions.

The versatility of industrial curtains has allowed many industries to adopt them for the following applications:

- Auto body shop bays

- Cleanroom dividers

- Cold storage curtains

- Containment or overspray curtains for spraypaint, sandblasting, sparks, smoke, or humidity

- COVID-19 partitions

- Curtains for industrial showers

- Hazmat or flex room curtains

- Loading docks

- Outdoor industrial curtains

- Outdoor restaurant enclosures

- Plane partitions

- Room or machining dividers

- Warehouse walls and dividers

- Woodworking curtains

What Are Industrial Vinyl Curtains?

Vinyl curtains are an ideal, inexpensive solution for companies wishing to separate spaces for quieter work or privacy, for temperature management, or to simply divide different areas of equipment. They allow facilities to easily create divided areas in warehouses, cold storage facilities, flex buildings, data centers, and other industrial buildings, but with the option of utilizing clear vinyl to maintain sight lines. Vinyl curtains are typically composed of durable yet lightweight material that, unlike some fabrics, will resist moisture and oils.

What Are the Benefits of Vinyl for Industrial Curtains?

Manufacturers use vinyl for industrial curtains to imbue their products with many advantages. At Adams Plastics Inc, we provide the materials to create these industrial curtains. These curtains can:

- Avoid contamination. Creating a wall with vinyl curtains allows the user to avert cross-contamination and restrict contaminants to one segment of a workspace.

- Control temperatures and improve air quality. Vinyl curtains are especially beneficial in temperature-controlled environments. Cold storage curtains act as a solid barrier at entryways to minimize air loss to maintain a certain temperature, and vinyl curtains in entryways are highly effective at minimizing the loss of energy brought by escaping heat or cold. Manufacturers also sell insulated curtains for enhanced climate-control capabilities.

- Create an alterable division of space. Unlike brick walls, vinyl curtains are highly flexible and versatile, allowing the user to better manage a space through equipment rearranging or process separation. Users can easily move them around as needed, or even store them when they are not in use.

- Clean easily. Users can clean vinyl curtains easily, sterilize them, or even have manufacturers add an antimicrobial coating. This is useful in facilities processing sensitive products. Also, this cleanability aids in the maintenance of these curtains throughout multiple uses.

- Control pests. Industrial vinyl curtains are too heavy for pests such as insects to penetrate.

- Decrease noise. Vinyl barriers cut down on noise pollution, providing sound insulation from the noise that workers or equipment produce within segments of an open workroom or manufacturing area.

- Increase visibility and worker safety. Vinyl curtains can provide transparent partitioning that allows workers to see through them to other employees and equipment. Particularly in industrial applications, unobstructed sight lines are important for managers to monitor workplace safety.

- Optimize facility space. Vinyl industrial curtains allow facilities to use their space efficiently without having to structurally modify the building. Users can install them to create smaller or more private work areas or retract them to create a larger space.

- Reduce costs. Vinyl curtains are cheaper than other partitioning alternatives like walls or panels, and users can reuse them in different locations. In addition to energy savings, transparent vinyl curtains also allow light through, which saves money that would otherwise be allocated for additional lighting. Also, vinyl curtains may be recyclable.

Vinyl Plastic From Adams Plastics Inc.

A leading supplier of PVC film, laminate, imitation leather, and more, Adams Plastics is committed to offering our clients high-quality, customized plastics along with superior customer service to fulfill all their vinyl and recycling needs. To find out more about our product line, contact us or request a quote today.

Polyvinyl chloride (PVC)—sometimes called vinyl—is a plastic material that comes in many variations, such as rigid or flexible, clear and opaque, and glossy or matte. It is widely available in film form, which is used to manufacture a wide range of parts and products for various home and business needs.

One of the most common manufacturing processes PVC film undergoes is welding. Through this process, it is turned into many different components for a diverse set of industrial and commercial markets, such as adhesive decals, automobile and boat seats, and medical bags.

Below, we provide an overview of the PVC welding process. We highlight what it is, what benefits it offers, how it is used, and what techniques are available.

What Is PVC Welding?

PVC welding is a plastic welding process used to permanently join separate pieces of PVC. It involves heating and/or melting the material at the join surfaces, pressing the pieces together, and allowing them to cool. Once the material on both pieces has cooled, the two pieces are bonded together at the molecular level.

Advantages of PVC Welding

Compared to other bonding methods, PVC welding has numerous advantages. For example:

- It can bond material without requiring mechanical fasteners or adhesives, which helps reduce material and equipment costs.

- It can join materials that are difficult to bond with solvent.

- It can assemble components with complex geometries or unusual bonding angles.

- It can form an airtight seal.

- It can create joined assemblies without adding a significant amount of weight.

Even in manufacturing and assembly projects where fasteners or adhesives are appropriate, welding offers unique benefits that can make it a better option. These include:

- Less surface preparation requirements

- Shorter cure and set times (depending on the welding method)

- More ergonomic joints and aesthetically pleasing bonds

- Better recyclability

Applications of PVC Welding

The above advantages and benefits make PVC welding a popular manufacturing method across a wide range of industries, including:

- Aeronautics

- Agricultural

- Automotive

- Industrial

- Marine

- Plumbing

PVC Welding Techniques

There are many PVC welding methods available, each of which has distinct characteristics that make it suitable for different joining applications.

Friction Welding

Friction or ultrasonic welding relies on friction to heat and fuse two pieces of PVC together. The pieces move relative to one another as a lateral force displaces them. This method is commonly used by manufacturers in the aerospace and automotive industries.

Extruded Bead Welding

Extruded bead welding involves the application of hot plastic between two sections of PVC. Once the plastic is applied, the sections are pressed together to form the bond.

Hot Gas Welding

Hot gas welding utilizes heat guns to soften a filler rod and the join surfaces on the PVC pieces before they are pressed together. This method is often utilized for small plumbing fittings, water tanks, and other industrial parts and products.

Hot Plate Welding

Hot plate welding employs a heated metal plate to heat the join surfaces before they are pressed together. The surface of the plate is coated with PTFE to prevent the PVC from sticking to it.

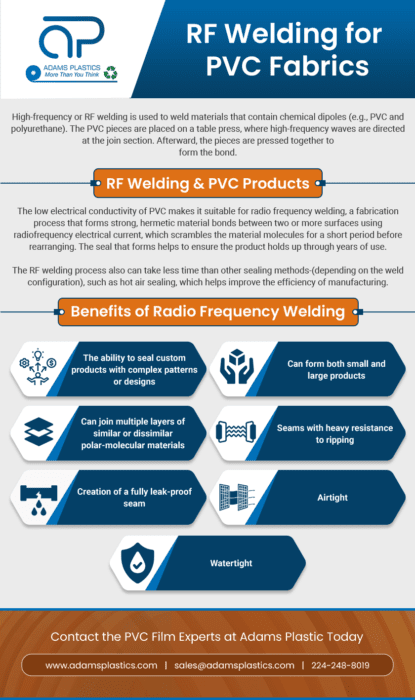

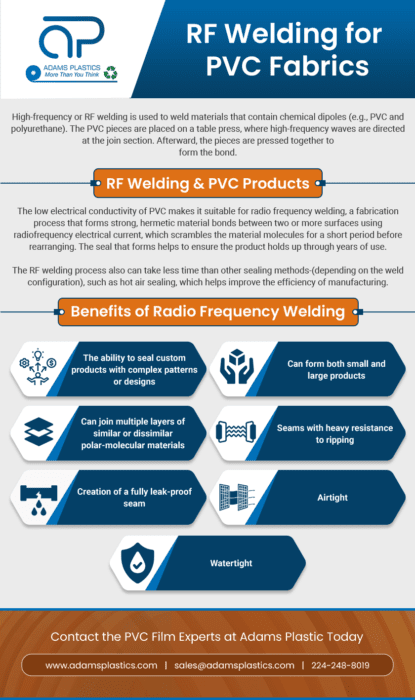

High-Frequency Welding

High-frequency or RF welding is used to weld materials that contain chemical dipoles (e.g., PVC and polyurethane). The PVC pieces are placed on a table press, where high-frequency waves are directed at the join section. Afterward, the pieces are pressed together to form the bond.

Solvent Welding

Solvent welding uses solvents to soften the join surfaces of the PVC pieces before they are pressed together. When the solvent evaporates, the pieces reharden, forming a durable bond.

Laser Welding

Laser welding utilizes a laser to heat the join line between two pieces of PVC as they are held together. The heat melts the material at the join line, forming the weld.

Induction Welding

Induction welding involves the placement of a conductive metal piece between the two pieces of PVC. A high-frequency generator is then used to heat the metal until it softens the surrounding plastic material. Once the two pieces are sufficiently softened, they are pressed together.

Contact the PVC Film Experts at Adams Plastic Today

PVC welding plays a key role in the manufacture of many industrial and commercial products. While the low cost of the material makes it a popular option for many manufacturing projects, it is important to source the material from a reliable supplier that can readily adapt to changing production needs. Otherwise, it may be difficult to accommodate greater or lesser demand in the future.

Looking for a PVC film supplier you can trust to meet your business needs on your schedule? Adams Plastics is the ideal partner. We are an industry leader in the supply of PVC films, laminates, imitation leather, and more. For more information on our products, request a sample or request a quote today.

At Adams Plastics Inc, a

At Adams Plastics Inc, a